About the Project

The City and County of Honolulu awarded Hensel Phelps the $149 million Kailua Regional Wastewater Treatment Plant (KRWWTP) project located in Kailua, Hawaii. The project is part of a 25 year, $4 billion consent decree between the City and County of Honolulu and the EPA that will upgrade and expand several existing plants within the County.

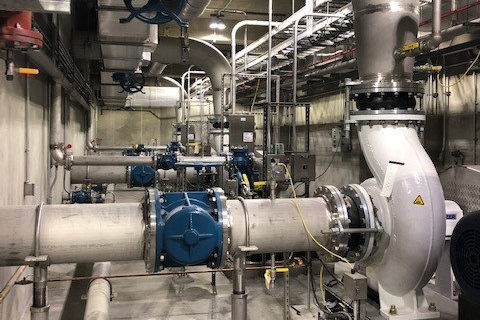

The KRWWTP project includes construction of the Tunnel Influent Pump Station (TIPS), Mini Kailua Influent Pump Station, Generator/ Electrical Distribution Building, Fuel Tank Pad, Headworks Facility, Sewer Pump Station and Force Main. The work also involves site utility and drainage system improvements. The TIPS features a 90-foot diameter, four-level cast-in-place concrete structure that extends over 100 feet below grade and two levels aboveground.

This project is one component of the Kaneohe/ Kailua Sewer Tunnel Project that is intended to convey wastewater flows from the Kaneohe Wastewater Pretreatment Facility to the (KRWWTP) and provide storage for peak wet-weather flows. The plan is to reduce overflows that occur when wastewater flows exceed the capacity of the existing KRWWTP.

Hensel Phelps self-performed the installation of the mechanical process piping, structural concrete, and other miscellaneous items for the project.

“Rather than idly standing by and accruing claim damages, Hensel Phelps proposed solutions on several occasions to re-sequence activities with the tunneling contractor ensuring that both contractors could cohabitate and continue to progress on their respective projects. It by no means was a simple feat nor efficient to construct in such conditions, but it allowed the overall project to be completed two weeks before the deadline.”

— Lori M.K. Kahikina, P.E.

Director, Dept. of Environmental Services

City and County of Honolulu

Challenge

PCB-Contaminated Soil

At the Kailua RWWTP site, Hensel Phelps had to address the removal of polychlorinated biphenyl (PCB) contaminated soil, a condition identified during excavation of the tunnel. As part of the project, Hensel Phelps was required to install caissons. The problem with PCB-contaminated soil is that once those caissons touch the soil, they are deemed contaminated as well.

Solution

Conducting Soil Testing to Identify the Contaminated Area

The presence of PCB-contaminated soil could have crippled the project from a schedule and financial standpoint, but instead of assuming the entire site was contaminated, Hensel Phelps hired local environmental consulting firm Inclusion Consulting LLC to conduct soil testing throughout the site at varying depths to create a PCB-contaminated soil management plan.

Result

Removing the Contaminated Soil While Preserving the Schedule & Budget

The soil management plan allowed Hensel Phelps to identify locations and depths of contamination during excavation, so contaminated soil was removed and disposed of as required by law and the rest of soil could be reused. So instead of costing several millions of dollars in disposal fees and a potential six-month delay, budgeted project allowances were able to cover the cost and the isolated removal did not affect the schedule or exceed the budgeted costs of the City.